Our Work in Action

When this air system couldn't stay dry, we custom-sourced and engineered this aftercooler system to outperform. Designed to deliver cleaner, drier air and extend the life of critical dairy components, this configuration outperforms standard OEMs by cooling compressor discharge air closer to ambient temps- removing moisture before it enters the pneumatic system. Results? Absolutely 0 water in the parlor

"Can't be done" doesn't stop us. We installed dual TXVs to retrofit a half-century old cooling system that failed, keeping a critical operation running - no full replacement required. 3 months in, still running strong. Innovative solutions. Zero shortcuts.

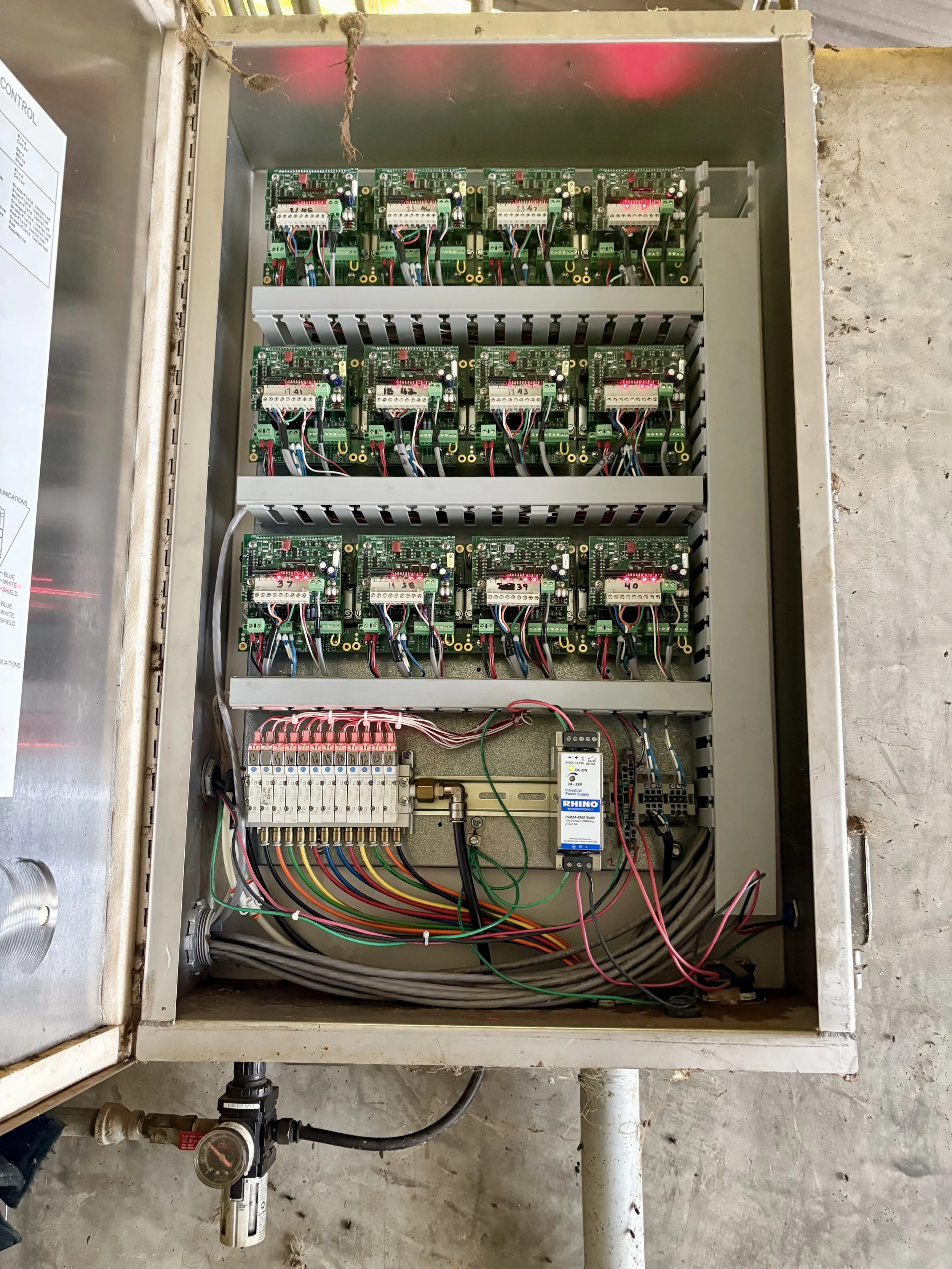

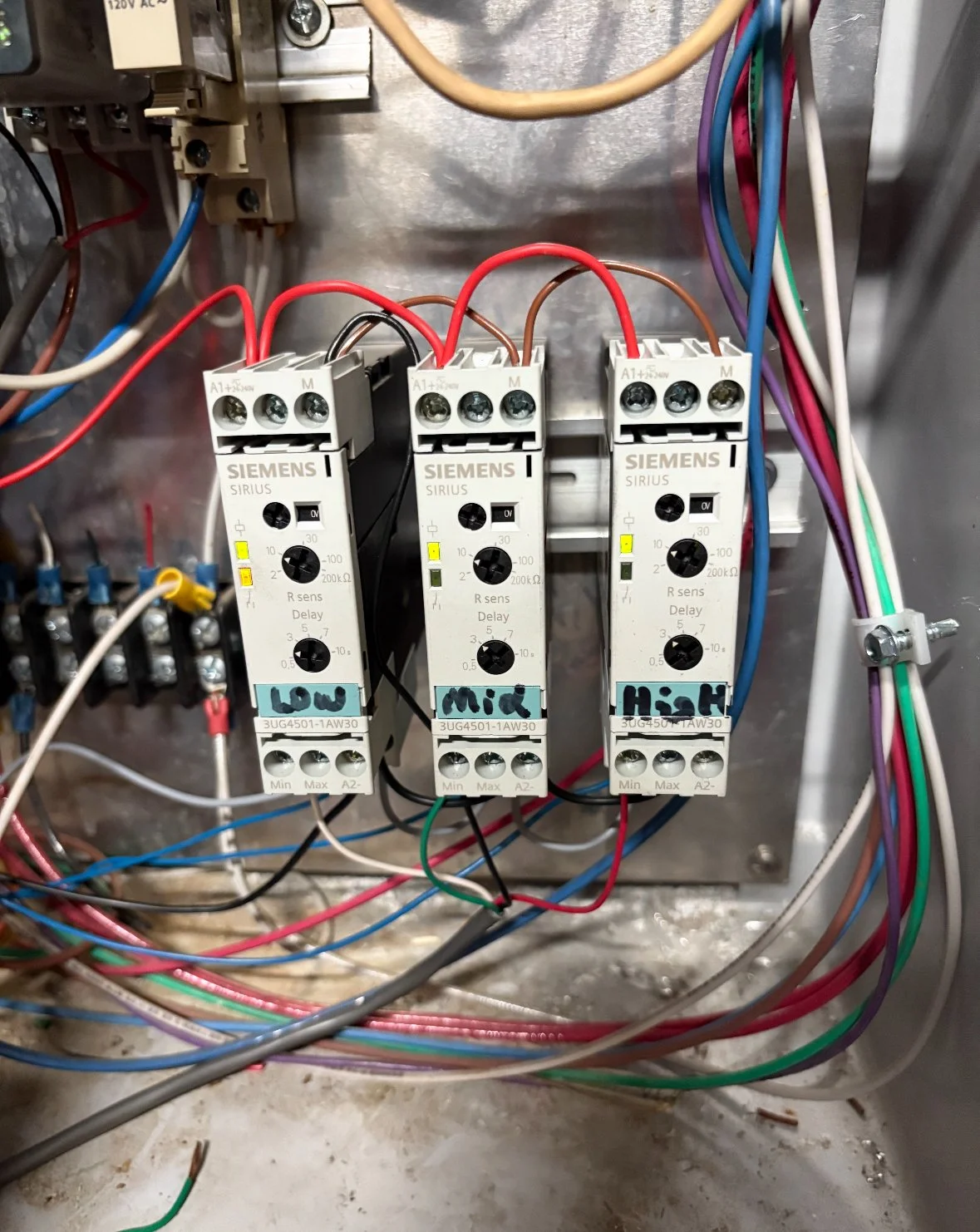

Implementing unique solutions: retrofitted liquid level controls into this vat to optimize cooling and milk flow

This liquid level relay communicates to the control inside the tank in the previous picture, replacing frequently failing float probes. No more replacement costs, and the pump operates at a lower speed, increasing cooling efficiency and milk storage duration.

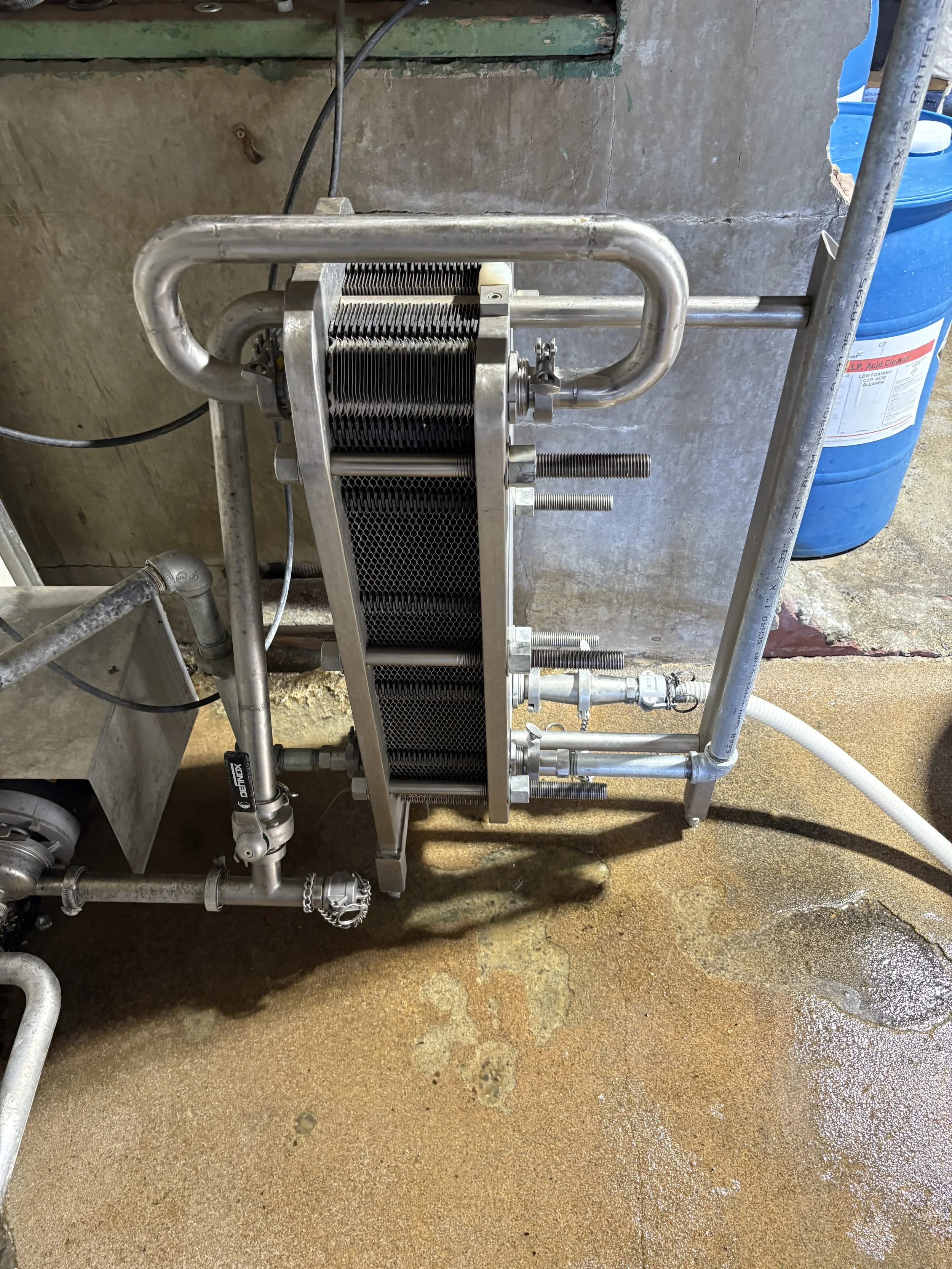

Custom-sourced and plumbed this like-new heat exchanger, delivering excellent value and reliability

Performed a complete startup of this dairy barn that had been inactive for years, sourcing needed parts, verifying equipment function, and restoring full operation.

Field calibration of pulsation and vacuum parameters during live milking. Verifying pulsation ratio, timing, and vacuum response to ensure peak system performance and equipment longevity